Smart Manufacturing Feast Opens

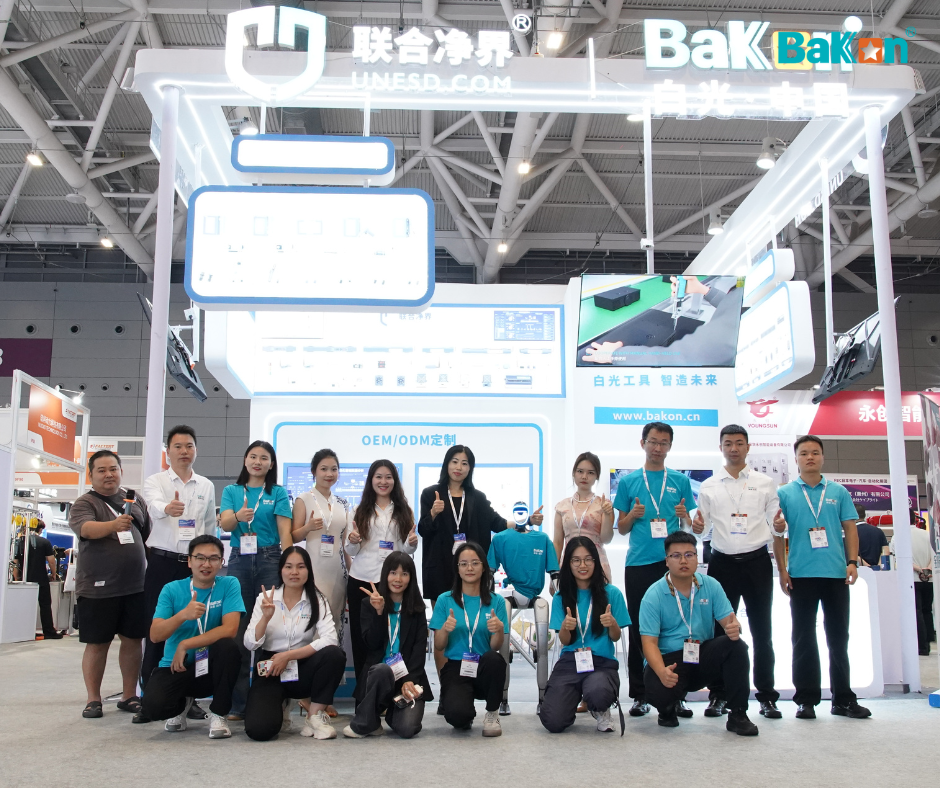

In October 2025, BAKON made a dazzling appearance at NEPCON ASIA 2025, showcasing its three core technology matrices alongside the “Smart Reception Officer” Unitree Robot G1. With breakthroughs in “Intelligent Screw Fastening · Precision Soldering · Electrostatic Control,” BAKON redefined the new height of China’s electronic manufacturing.

The booth attracted professional buyers from around the world, setting a record of over a thousand visitors in a single day. The event garnered extensive coverage from domestic and international media, with BAKON’s technologies topping industry trending lists.

Core Highlights · The Three Core Technologies

Intelligent Screw Fastening · Benchmark of Automotive Electronics Precision

The ZH30LD Intelligent Electric Screwdriver, integrated with MES/ERP systems, achieves fastening precision of ±0.02 mm, ensuring a 99.9% yield rate in new energy vehicle (NEV) battery module assembly.

The ZH04LD Counting Electric Screwdriver combines fastening, counting, and traceability functions, featuring a dynamic data display that shows torque, angle, and status in real time. This innovation has boosted production efficiency by 35% for leading Japanese automakers and secured multiple bulk purchase orders on-site.

Lead-Free Soldering · A New Benchmark for Green Smart Manufacturing

The BK3300D Vortex Heating Intelligent Soldering Station offers 3-second rapid heating and ±0.5°C ultra-precise temperature control, successfully completing IGBT module lead-free soldering validation.

Meanwhile, the BK2600 Intelligent Temperature Control System, powered by an IoT data platform, optimizes soldering curves, helping NEV manufacturers reduce energy consumption by 18% while achieving a 99.7% soldering yield.

Electrostatic Control · Nano-Level Safety Guardian

The BK582 DC Ionizer achieves a 99.999% static elimination rate at the 10 nm level, recognized by TSMC and Samsung, making it a must-have for semiconductor cleanrooms.

The UW350 Series Ionizing Bars continuously release high-concentration negative ions, meeting the stringent requirements of advanced cleanroom environments.

Tech Star · Unitree Robot G1

As the “Smart Reception Officer” of this exhibition, Unitree G1 handled over 2,500 visitor interactions, with interactive videos exceeding 10,000 global views.

Equipped with multimodal intelligence and an emotion recognition system, G1 can perceive visitors’ tone and expressions in real time, dynamically adjusting its voice-guided tours and demonstrations.

G1 perfectly embodied the fusion of technological innovation and human interaction, highlighting the global influence of China’s smart manufacturing while infusing the exhibition booth with a futuristic flair.

Strategic Outlook · Executive Interview Highlights

In an exclusive interview with Auto Manufacturing Network, BAKON Vice General Manager Sun Xi emphasized:

“New energy and automotive electronics manufacturing will be key growth drivers in the future. We’ve launched our ESD Super Static Protection Platform 2.0, tailored to NEV electronic manufacturing needs, providing end-to-end static protection from wafer to module.

On the technology front, our intelligent fastening and lead-free soldering technologies continue to evolve. With IoT-enabled BK series soldering stations, we’ve achieved a 20% reduction in energy consumption and a 99.8% yield rate.

BAKON will keep investing in R&D, deepening partnerships with chipmakers and automakers, and driving collaborative innovation across the industry chain — together, we will usher in a new era of smart manufacturing.”

Exhibition Highlights · Global Spotlight

- Visitor Data: Over 1,000 visitors daily, with 40% international attendees from countries including Turkey, Colombia, Brazil, and Mexico.

- Media Coverage: Featured by CCTV, Reuters, and Shenzhen TV, with BAKON’s technologies ranking in the Top 5 trending topics of the exhibition.

- Social Media Impact: Interactive videos surpassed 10,000 global views.

Future Outlook · A Triumphant Journey to Munich

Driven by innovation and empowered by technology, BAKON continues to lead the way in intelligent manufacturing.

From NEPCON ASIA Shenzhen to the 2025 Munich Electronics Fair, BAKON builds on its three core technologies — Intelligent Screw Fastening, Lead-Free Soldering, and Electrostatic Control — to continually push the boundaries of electronic manufacturing.

We look forward to meeting again in Munich this November to embark on a new global chapter of electronic manufacturing excellence!

Explore BAKON’s precision soldering tools, smart screwdrivers, and anti-static solutions, and stay updated on LinkedIn: BAKON LinkedIn. and website: www.bakontools.com

MEDIA CONTACT: grace@bakon.cn